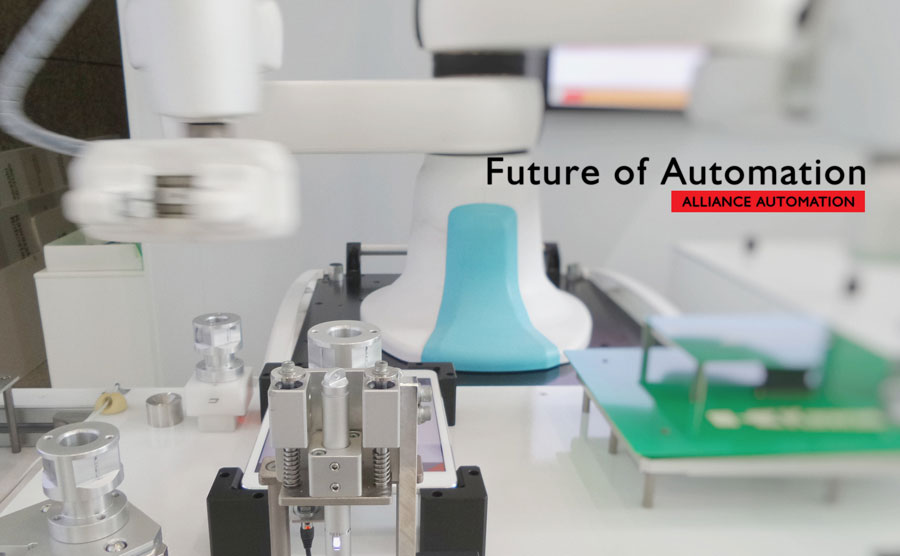

Automation combined with artificial intelligence (AI) will transform the nature of work and workplace. Innovation and technology will establish much faster growth in industrial automation. Industrial automation will generate explosive growth with technology related to nanotechnology, nanoscale assembly systems, MEMS and nanotech sensors, PLCs, HMIs etc. Which can measure everything and anything.Complex adaptive systems and multi-processing is taking over from real -time systems. The future belongs to nanotech, remotely connected and adaptive systems.

PLC in Industrial automation

PLC is a programmable logic controller. PLC is an industrial computer used as a standalone unit and is used in a network of PLCs to automatically control a process or perform a specific function. PLC uses a different forms of connected sensors to take information from outside world such as temperature of a liquid, speed of a fan etc. PLC can influence and impact the future if industrial automation to control processes.

The current trends in industrial automation includes increased use of analytics, increased use of PLCs, PACs and cloud based monitoring control and data acquisition (SCADA Systems). These trends are going to create ripple in the industrial automation market. These trends are globally and going to increase exponentially.

Every industry is going thru technological changes which is bringing great advancements in the machinery, techniques and technology itself. This is helping industries in automating their operations without significant intervention from humans and is also providing automatic performance or data to visualize and control operations remotely.

New Technology and advancement in industrial automation is the driver of progress. From conception to the introduction of the collaborative robots, the changes in the technological developments continuously shape the industrial automation landscape.