Working hours:Mon - Sat 9:00 - 18:00 Call Us: +91 124 4477 951

Industrial Solutions

Commited to help building a smarter infrastructure

Foolproof System

In an age with increasing costs and additional demands, finding a way to automate some business processes using technology may be the key to solving problems. At Alliance Automation, our engineers are problem solvers who use the latest in technology to create foolproof automation systems for businesses.

Put to light Concept

In assembling /making a part, it is very difficult for an operator to differentiate models and assemble accordingly. So, reading the model no with a barcode/RFID, the control unit makes the light “On” of the material correspondingly and makes the light “off” when the material is picked up.

Torque Wrench

Alliance Automation offers solution for the torque data monitoring from torque wrench on the shop floor.

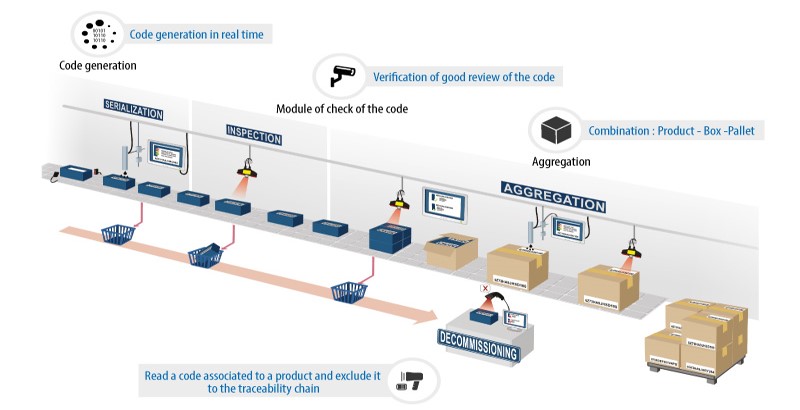

Line traceability

In a processing line, the product goes under several stations. Each product is given unique code, at the end of process in each station, the data is recorded against the Code. Missing process & re-processing of a product can be eliminated by pre-verification at each station. A product can be traced easily (which station is it processing at) and serialization of an assembly is maintained.

Andon Systems

The term “Andon” refers to a visual system used to notify management, workers and maintenance of either process or quality problems.

Production Monitor Display

Alliance Automation has industrial displays and andon systems that companies have implemented to complement and help drive their manufacturing processes. Our industrial LED products provide the perfect answer to all your communication needs in the industrial environment.

Dot Matrix Display

Alarms in a shop floor can be displayed, Such that supervisor of the line can easily troubleshoot the alarm spot. Production break down time can be reduced

SCADA Systems

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that allows industrial organizations to:

• Control industrial processes locally or at remote locations

• Monitor, gather, and process real-time data

• Directly interact with devices such as sensors, valves, pumps, motors, etc. through HMI software

• Record events into a log file

• Control industrial processes locally or at remote locations

• Monitor, gather, and process real-time data

• Directly interact with devices such as sensors, valves, pumps, motors, etc. through HMI software

• Record events into a log file

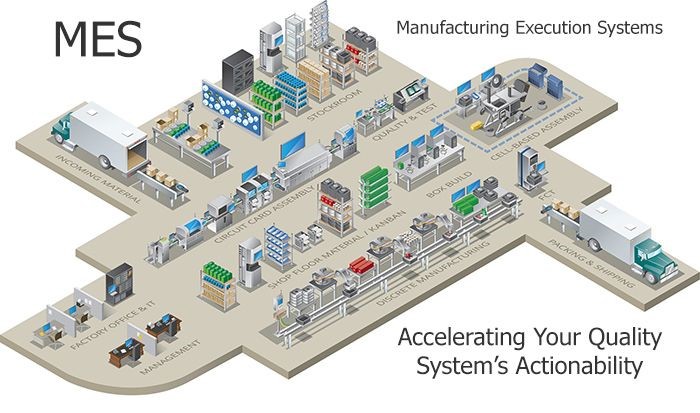

Manufacturing Execution Systems

Quality Data Capture

All the process systems are centralized by connecting each system with the Central Control unit. The central control unit captures the data from each process system time to time and saves the data in the Central server.

All the process systems are centralized by connecting each system with the Central Control unit. The central control unit captures the data from each process system time to time and saves the data in the Central server.

Alliance Automation

Office

“passion for automation“ has an address

locations

inGurugram